Custom Decoration

High Quality, Eco-Conscious Apparel Decoration

Everywhere recycled cotton garments are easy to customize with your logo, message + artwork. They’ve been designed and tested to accommodate the most widely used decoration techniques on the market.

We have years of hands-on decoration experience and work with a network of partners based within a 10 mile radius of our LA headquarters.

Our sustainable customization services include screen printing, direct-to-film, direct-to-garment, embroidery, and garment dyeing.

Learn more about our eco-friendly decoration & customization capabilities.

*Please note the minimum order quantity is 500 units per design across all decoration methods. For projects under the MOQ, please get in touch via the form below and view the FAQ section for how we can best work together. Thanks :)

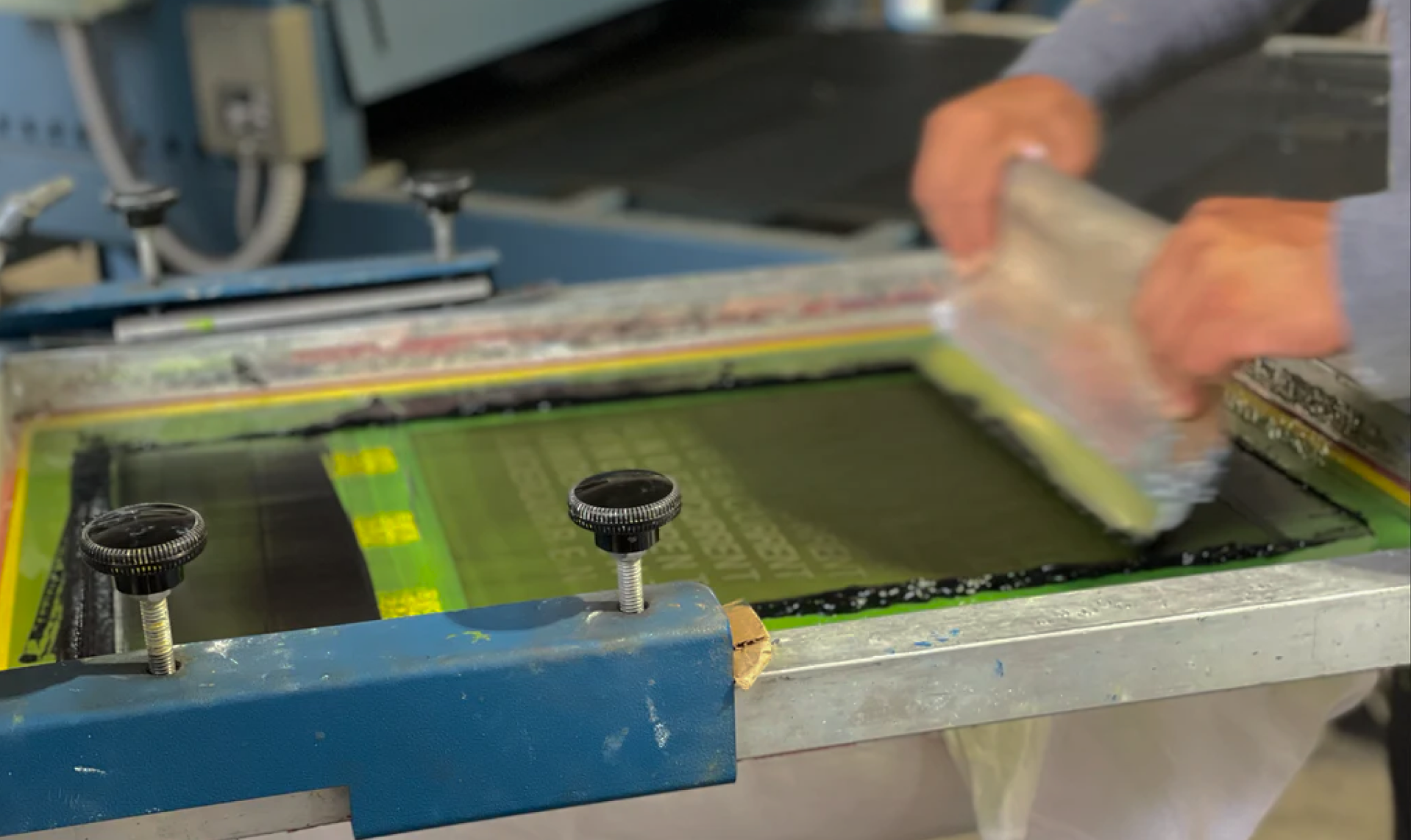

Screen Printing

Screen printing produces strong, saturated + opaque colors, looks more painterly, and has a smooth hand feel. This printing style is ideal for artwork with separated colors like logos, emblems + simple text. Screen printing is not ideal for artwork with gradients, full spectrum color, or small orders.

COLORS: Up to 4 colors (can add more but costs increase)

TURNAROUND TIME: At least 2 weeks

IDEAL FOR: Mid-large size corporations, sporting events + teams

COSTS: Cost-effective at high volume, involves set up fees

START A SCREEN PRINTING PROJECT

Direct-To-Film (DTF)

Direct-To-Film is a digital printing process that has no color limitations and works well for gradient, airbrush, and detailed artwork. It’s cost-effective for all order sizes, especially lower volume orders.

COLORS: Full spectrum

color

TURNAROUND TIME: At least 4 business days

IDEAL FOR: New businesses, small events, parties + team projects

COSTS: Most cost-effective for smaller orders.

START A DIRECT-TO-FILM PROJECT

Direct-To-Garment (DTG)

Direct-To-Garment is a digital printing process that has no color limitations and is best for photographic artwork and art with large areas of uninterrupted ink. DTG also works well for gradients, airbrush styles, and fine art. It’s not as durable as direct-to-film and prints can fade when washed, but DTG is a very cost-effective printing option for high volume orders.

COLORS: Full spectrum color

TURNAROUND TIME: At least 4 business days

IDEAL FOR: Large fashion brands, high volume merch + arts orders

COSTS: Cost-effective for high volume orders

START A DIRECT TO GARMENT PROJECT

Embroidery

Embroidery is ideal for simple artwork like logos, icons, and text. Monochromatic or color blocked artwork works best for this technique. Embroidery is expensive and less sustainable than other decoration options, but is great for high-end projects, elevated corporate apparel, and end of year gifts.

COLORS: Up to 4 colors

TURNAROUND TIME: At least 3 weeks

IDEAL FOR: Corporate gifting, schools + universities, streetwear

COSTS: High-cost technique

START AN EMBROIDERY PROJECT

image credit: Kate Leach Creative for The Corner Chair

Garment Dyeing

We can garment dye any of our white apparel to match the Pantone color of your choice and can tie dye. Custom color garments are locally dyed in Los Angeles using sustainable, bluesign certified reactive dyes. We can provide garment dyeing alongside any of our decoration techniques, or as a standalone service.

COLORS: Any single Pantone color or tie dye

TURNAROUND TIME: At least 4 business days (additional to decoration)

IDEAL FOR: Branded apparel, schools, corporations, fashion

COSTS: Higher costs for low volume, discounts for 500+ units

START A GARMENT DYEING PROJECT

See Our Work:

Coachtopia, Atmos, Santana Bellas, Syracuse Cultural Workers, Featured Projects

Please contact us with any questions or custom projects

Decoration FAQ

For orders below the 500 unit MOQ, please fill out the above form making sure to indicate the quantity bracket that best reflects your needs and including the actual number of units in the message section.

We will be happy to connect you with an experienced and trusted decoration partner in the Los Angeles area who will take you through the printing process from start to finish.

Rest assured that despite working with a third party decorator, you will only ever receive Everywhere's 100% recycled cotton blanks. Guaranteed.

We do our research when it comes to sustainability and textile decoration and have made intentional decisions about the kinds of inks and decoration techniques we offer.

While options are limited, we prioritize using decoration techniques that involve the least amount of chemicals when possible and are always on the hunt for sustainable decoration methods we can offer our customers.

Most importantly, we want our customers to have transparent information about textile decoration to help inform their decision and make people aware of the sustainability considerations around apparel decorating.

Below are a few of the considerations to be aware of behind each type of decoration we offer on our garments:

Screen Printing: For screen printing, we use only PVC-Free and phthalate-free or waterbased inks. On dark garments, we avoid processes that involve the use of ammonia discharge inks that later drain into our water supply.

PVC-Free inks are considered safe and effective alternatives to conventional plastisol inks. Most eco-friendly screen printers have these inks in stock, and they will print exactly like traditional plastisol inks, just without as many toxic chemicals.

Direct-to-Garment Printing: Direct-to-garment printing on white garments uses waterbased inks and requires no pretreat chemicals to maintain colorfastness. On dark garments, however, pretreat chemicals are used to lock the inks onto the fiber. This pretreat will wash off when the shirt is washed and can contaminate water this way.

Direct-to-Film Printing: Direct-to-film printing involves using waterbased inks to print on a film that is then backed with an adhesive powder and heat pressed onto textiles. This method enables lower volume printing with more colors at a more affordable price.

Next Generation Ink Technologies: In addition to screen printing and digital printing, we also offer next generation ink technologies, including some of the most innovative + sustainable inks on the market like AIR-INK and Algae ink.

AIR-INK is a sustainable ink option produced from sequestered air pollution. The process of the ink's creation offsets carbon and helps to remove pollutants, heavy metals, and toxins from the air. Algae Ink is another eco-friendly, renewable ink option that reduces carbon and is made from algae waste. These inks currently only come in black.

Embroidery: Embroidery threads can be cotton or polyester and usually involve a backing made of a synthetic material. 100% cotton threads, while more expensive, are more sustainable as they are biodegradable at end of life.

Garment Dyeing: Custom color garments are locally dyed in Los Angeles using bluesign certified reactive dyes.

Different inks are used depending on print decoration method. For screen printing, we use only PVC-free and phthalate-free or water-based screen printing inks.

We recommend using water-based screen printing inks on light colored garments and PVC and phthalate-free inks on dark garments.

We do not recommend waterbased screen printing on dark color garments as this process requires a chemical discharge to cancel out the color of the fabric fibers. On any fabric, not just 100% recycled, the discharge chemicals used with water-based screen printing on dark colored garments can bring out some inconsistencies in the base fiber of the fabric. This chemical discharge is not ideal from a cleaning and disposal perspective, which is why we typically recommend using waterbased inks primarly on white or light colored garments.

On request, we also offer printing using AIR-INK + Algae Ink. These inks currently only come in black, and we can quote projects using them upon request. Digital print processes, including direct-to-garment and direct-to-film, use waterbased inks.

Printed or embroidered areas of garments we receive back for recycling are removed from the garment and processed through a downcycling shredding line. These areas of the garment are turned into products like insulation and carpet padding. The rest of the garment is processed through our cotton-to-cotton recycling process into new textiles.

Unfortunately, due to the residue of the inks on printed areas of the textile, printed or embroidered areas cannot be respun into new yarns.

Recycled cotton can have specks and color variations by nature. When garment dyed, some of this texture can show through in the dyed product. We do our best to keep these types of minor contaminations to a minimum and achieve pure color saturation throughout the garment. However, by nature of the material being recycled, there can be specks or subtle textures in the dyed garment. We quality control out any highly noticeable instances of contamination before they are dyed.

We expect clients to come to us with print-ready artwork in high resolution. Acceptable file formats are: hi-res PNG, vector files (.eps or .ai), or .psd files. In some cases, we can help provide design support to vectorize artwork at an hourly fee of $45/hr.

Below is an outline of our artwork approval process:

- After your order is paid, we provide a digital mockup for you to confirm prior to print production within 24 hours. In the case of garment dyeing, we will need approval on a Pantone color to match.

- Once approval is provided, we will proceed straight into decoration production.

- If you need a physical sample of your product we will quote you . Receiving a physical sample can add up to 2 weeks to the overall production timeline.

Once final artwork is approved and the invoice has been paid, project turnaround time for direct-to-film and direct-to-garment is 4 business days, screen printing is 2 weeks, embroidery is 3 weeks, and garment dyeing is 4 business days (additional to decoration time).

We can accommodate rush orders upon request. If an order is needed before our standard fulfillment times below, please let our team know, and we will do our best to accommodate it. Your order may be subject to rush fees.

Standard fulfillment times:

Screen Printing: ~20 business days

Direct-to-Film: ~10-15 business days

Direct-to-Garment: ~10-15 business days

Embroidery: ~20 business days

Garment Dye: ~20 business days, additional time with printing

Please note that decoration fulfillment times start when the order is paid and artwork is approved for production. For decoration orders that involve both garment dye and print decoration, the fulfillment time is additive.

Yes, we offer full package, high-volume product development services and can manufacture custom fabrics, garments, and white label collections. We specialize in knit and woven material development with recycled fibers, and can create recycled textiles, apparel, and trims in a variety of cuts and colors. Our materials have passed the most stringent global brand compliance standards.

Check out our Product Development Services and Branded Collections pages to learn more.